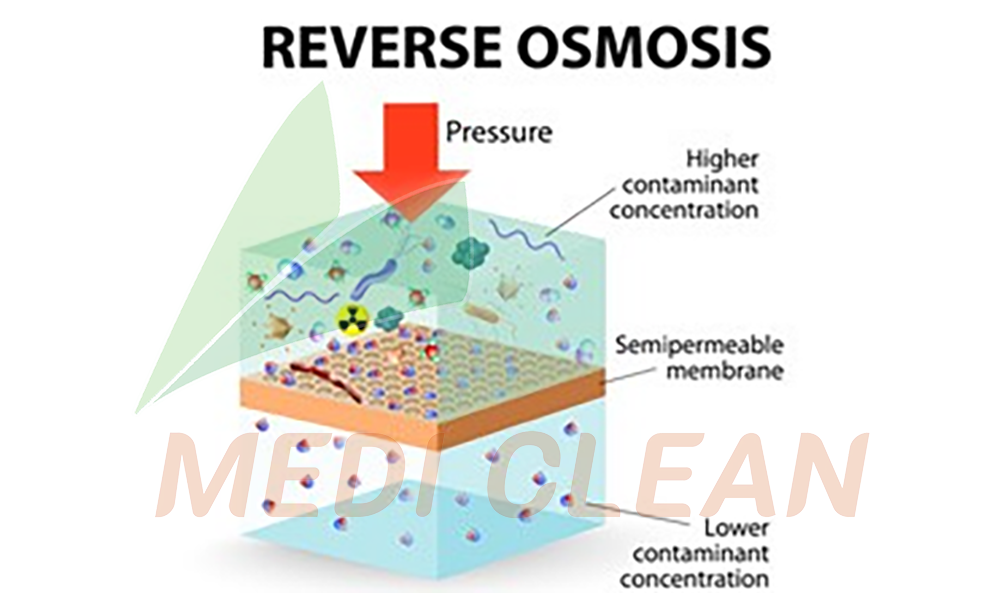

What is Reverse Osmosis?Reverse osmosis (R/O) is a water treatment process in which water is forced through a semi-permeable membrane that has very small holes or "pores". Clean water passes through and impurities that are too big to pass through the membrane are left behind and flushed away. In a w...

Reverse Osmosis

Product Type:WATER TREATMENT

Product No:

Thickness:

Size:

Material:

Monthly production capacity:

Applications:

Remarks:

Product Information

What is Reverse Osmosis?Reverse osmosis (R/O) is a water treatment process in which water is forced through a semi-permeable membrane that has very small holes or "pores". Clean water passes through and impurities that are too big to pass through the membrane are left behind and flushed away. In a word, it is a machine to make pure/ultra pure water

How Do I Know Which Size Unit to Buy?

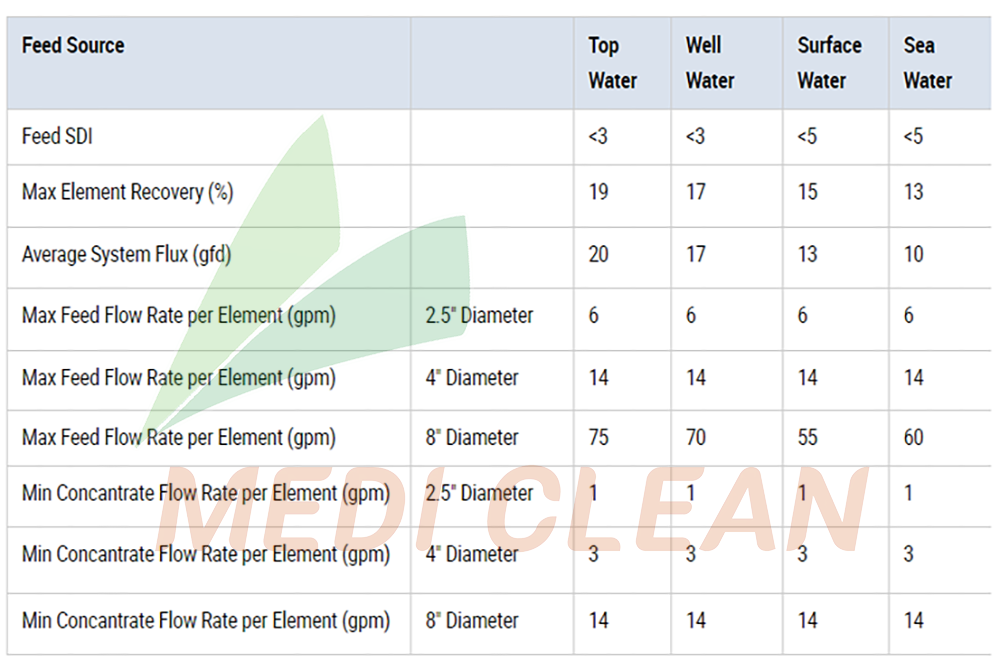

General guidelines for modeling an RO system to take into consideration are the silt density index (SDI) measurement of the feed water after pretreatment. Derived from experien- ce, limits on permeate flux and element recovery for different types of waters are based on correlation of the SDI value with membrane fouling and mineral content with element re-covery, respectfully, for different types of waters. These ge- neral limits shown in Table 1 below serve as boundary condi-tions when designing a RO system. A system designed with high permeate flux rates for example is likely to experience higher fouling rates and more frequent chemical cleanings. Due to high salinity (>36,000 ppm TDS), seawater system de-signs are further limited by the osmotic pressure and durabi- lity of the membrane elements.

Material of reverse osmosis system?

We have different material for different application. Before choosing RO System and Type please contact with our Pro- fessional CHUNKE technical service.

1.Tanks: Fiber glass or Stainless Steel 304/316

2. Pipes: U-PVC or stainless steel filter

3. Frame: Stainless Steel 304 or 316

4. Filter Housing: U-PVC or SS304 or SS316

5. Memrane Housing: FRP or SS304 or SS316

Benefits of Reverse Osmosis (RO) Systems

RO system requires very less energy for its working.

It requires very low maintenance.

The RO system uses an automated technique called cross-flow to clean its clogged membrane.

RO system, when used in water filters, eliminates 98% of the impurities from tap water.

The water produced by RO technology, when supplied to a gas turbine, improves operating efficiency, and increases output by more than 10%.

RO systems are cost-effective, and their price is continually decreasing.

RO systems do not make use of harmful chemicals, hence are used in many power plants.

Application

Solvents, Paints

Edible Oils

Petrochemicals

Water

Waste Water

Chemicals

Metal

Automotive

Electronics

Food and Beverage